“AZGRANATA” MMC

“AZGRANATA” LLC, established in 2011, is one of the largest manufacturers of alcoholic and non-alcoholic drinks in the South Caucasus. The plant operating in Agsu region covers an area of 14 hectares. The plant, supplied with modern equipment, that meets world standards produces preservative-free natural fruit juices, concentrates, compotes, lemonades, as well as wine and vodka products. The sections of fruit reception, fruit juice processing, tetra pack filling and packaging, bottle filling and packaging and compote production are operating at the plant. “AZGRANATA” has the capacity of producing 12 tons of fruit juice per hour. The plant, equipment of which is supplied from Germany, Switzerland, Italy, Bulgaria and France, also has a warehouse containing 2 million liters of finished products. Additionally, all necessary analyses to check the product’s suitability for chemical and microbiological, taste, flavor, aroma, appearance and sale are carried out in the laboratory of analysis inside the plant and the product’s compliance with hygienic standards is ensured.

The gardens of “AZGRANATA” LLC

Vineyards:

Since 2006, vineyards have been planted at an altitude of 600-700 meters above sea level in the Adnali plateau of the Great Caucasus mountains range, in the territory of Shamakhi region. Local and foreign grape varieties, which have their own place in the history of winemaking are grown in the gardens planted on 414 hectares of technical, as well as table grape varieties. Table grape varieties such as Sultanina, Prima, Ora, Kardinal, Alfons Lavalier, Centenial seedless, Crimson seedless, Thompson seedless, Red Globe, and technical grape varieties such as Madrasa, Bayanshira, Saperavi, Rkasiteli, Muscat, Merlot, Cabernet Franc, Cabernet Sauvignon, Riesling, Shiraz, Glera, Chardonnay are available in the vineyards.

Pomegranate gardens:

The pomegranate gardens of “AZGRANATA” LLC started to be planted in 2006. Pomegranate gardens planted in Hajigadirli and Garavalli villages of Agsu region currently cover a total area of about 350 hectares. Azerbaijan Gulovsha, Pink Gulovsha, Red peel, Thin peel, Bala Mursel and Red hybrid varieties are grown in pomegranate gardens following agrotechnical rules. Some of the pomegranate gardens are organic. Fruit production and farming methods are regularly checked by local and foreign experts at “AZGRANATA” LLC. A drip irrigation system is applied in the gardens.

Our Mission and Vision:

Since its establishment, “AZGRANATA” LLC has contributed to the increase in the volume of agriculture in the country’s economy and the development of the non-oil sector with its achievements in the fields of viticulture and pomegranate growing in Azerbaijan. It has also achieved a number of successes in promoting the “Made in Azerbaijan” logo in the world with its both fruit juices and wines. “AZGRANATA” LLC created a competitive local brand in the world market with modern technologies assuming centuries-old winemaking traditions of the Azerbaijani people.

Non-alcoholic drinks production sector:

The production complex, designed for processing 20 tons of fruit per hour, production of 8,000 pcs tetra pak 1 l, 9000 pcs tetra pak 200 ml, 4000 pcs glass bottles 1 l, and 4,000 pcs compote 1 l and is supplied with all necessary equipment. Besides, necessary works for the production of 8000 units of 1 liter and 8000 units of 500 ml lemonade per hour have been started in our enterprise.

fruit reception and preliminary processing section: it includes processing technologies of stoned, stoneless and seedy fruits.

pomegranate seed drying section: it includes Turkish-made brushing, fruit and seed drying equipment supplied with natural gas, sorting sieve and packing (800 kg bag) equipment. The end product is exported to various countries for the preparation of cosmetics and pharmaceutical preparations.

aseptic storage section: it includes a short-term high-temperature pasteurizer, aseptic storage tanks (56 units, 50 tons each, total 2800 tons)

pomegranate wines section: it includes the evaporation unit and the bottling unit.

raw material processing section: this includes sorting tanks, mixers and necessary equipment for syrup preparation

lemonade production department: it includes a production line designed for lemonade filling and packaging in 1 l, 2 l, 700 ml and 500 ml (in glass and plastic packaging).

tetrapak process, filling and packaging department: it includes sterilization, pasteurizing, homogenizing unit, 2 production lines of 1 l and 200 ml

bottling and packaging department: it includes pasteurizing, homogenizing unit, 1 production line of 1 l and 200 ml

compote production department: it includes fruit washing, sorting, cleaning and a production line. (In the off-season, 1 l and 200 ml juices are produced)

semi-finished product preparation and packaging department: it includes evaporation unit, ultra-filter and aseptic filling equipment for 250 kg barrels.

ancillary areas: it includes cooler units, a 3-stage water treatment system of 55 tons per hour, a ventilation system and maintenance department.

A special room attached to the laboratory operates to control the quality of the production area outputs.

Alcoholic drinks production sector:

It consists of a grape reception and preliminary processing line, distillation unit, preparation, storage and filtering units of wine and other alcoholic beverages. The wine filtration line produces 6000 bottles and the line for strong drinks produces 4000 bottles per hour.

The magnificent tasting room of the enterprise is elegantly designed. Even a small museum of winemaking has been set up here. The museum contains many ancient exhibits related to winemaking, wines from different years and books related to winemaking.

The types of drinks produced in this sector include:

Table wines and special wines, sparkling wines, fruit wines, cognacs, fruit vodkas, whiskeys, vodkas and special vodkas. Barrels used to store wines in the plant are made from South-Western European, Eastern European and American oaks. The perennial woody part of oak is used to make a barrel. AZGRANATA obtains these barrels from old and famous companies in France and Italy. Cork oak, which grows in the Mediterranean countries is used for making wine corks. The cork is cleaned and, after being kept still for 6-24 months, it is disinfected by cooking in boiling water and the tannins are washed away.

Export:

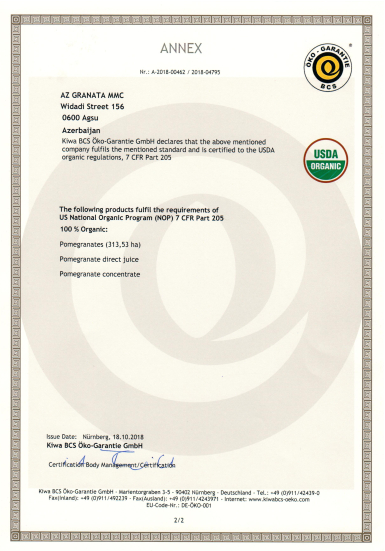

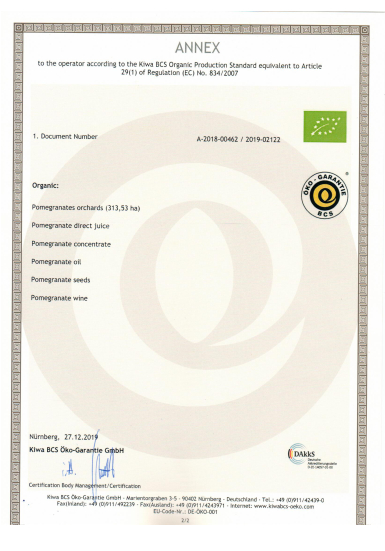

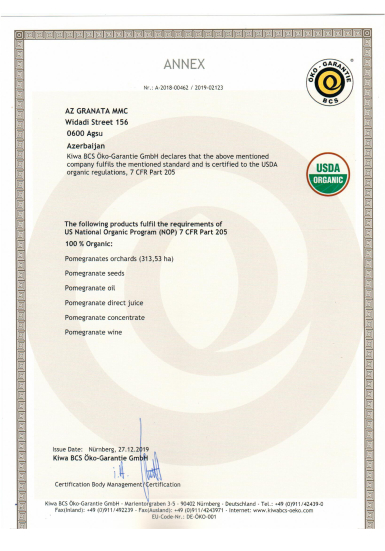

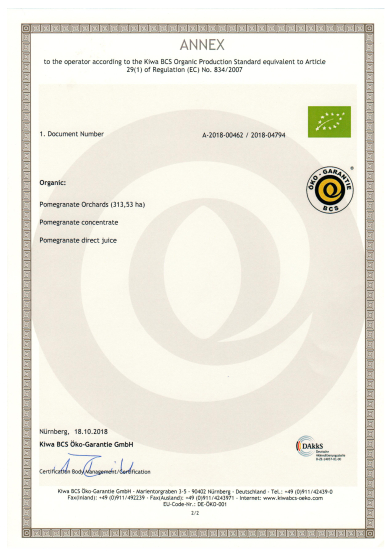

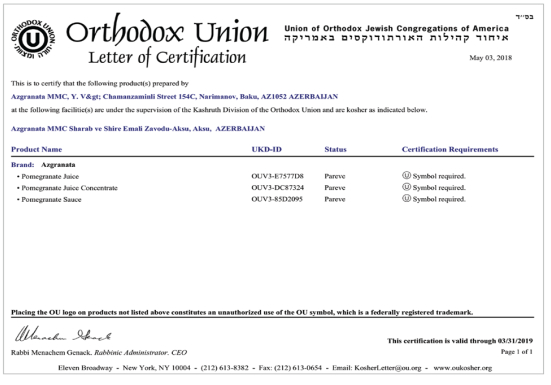

Both alcoholic and non-alcoholic beverages produced at the AZGRANATA plant are exported to several countries around the world. Pomegranate wines and concentrates as special products of the plant, also have a great market share among the country’s export products. The top list of the company’s exporters is dominated by the developed countries such as the USA, Canada, China, Germany, Israel, and Russia. AZGRANATA products have been certified organic by the Institute of KIWA GmbH of Germany. We also have the following certificates:

- BIO certificate (European Union)

- USDA Organic (USA)

- Kosher certificate

- ISO 22000: 2018 Food Safety Management System

- ISO 9001:2015 Quality Management System

- Halal certificate